General Description

Tongs Grab for transporting billets is designed with the advanced experience from home and abroad on the basis of our production experiences for many years with the advantage of no power consumption, no electromagnetic wave interference, reliable & safe in operation and flexible adaptability. Facts have proved that this lifting tool can load and unload steel billets freely without the cooperation of workmen on the ground, which is an ideal lifting tool used for handling steel billets.

Features

1. Basic Principle

When the tongs works, it utilizes the hoisting of the crane, lifting tool and billets’ weight to hold and unload the billets through the mechancal open-close dev ce of the tongs (sliding type, guide axis type and rotary type). The basic working principle is lever principle.

2. Operating Conditions

2.2.1 The temperature of the held material shall be not more than 1250 ºC.

2.2.2 It can be used indoors and outdoors. Simple and easy to install, just to hang it on the hook of crane. Easy to operate, just to operate the crane up and down.

2.2.3 The difference of holding width between the maximun to the minimun is less than 300mm (Model Ⅰ) and 600mm (Model Ⅱ), or else it will be unsafe.

3. Structures and Features

3.1 The structure is composed of main parts such as lifting hook or chain, pin, lifting beam, bottom beam, guide plate, connecting rod, automatic open-close equipment, etc. It is compact and failure points are few.

3.2 A tongs consist of a pair of tongs mouth, tongs arm and suspending arm. The tongs mouth is fixed on the tongs arm and the tongs arm and suspending arm are hinged by self-lubricating bearing and hinge axle.

3.3 The automatic open-close equipment is flexible and reliable in clamping and discharging the billets for its reasonable structure. The structure includes sliding type, guide spindle type and mechanical rotary type.

3.4 It clamps and discharges billets automatic without power drive, which is environment-friendly and energy economized product.

3.5 All these main joints adopt new technology of self-lubricating bearing to make the tongs durable and maintenance-exempted.

3.6 Lifting tool and cleat adopt alloy steel and the coupling bearing adopts quenched and tempered steel, with high intensity; the mouth of tongs adopts special kind of die steel that has good performance at high temperature.

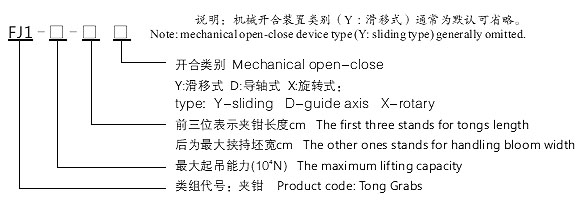

Model Designation

Guide for Model Selection

Please select the correct model as per the following guide.

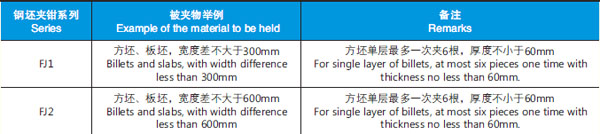

Select the correct product series according to the holding material as per the following table.

For tongs series FJ1, adopt structure A when the space between each two groups of tongs is no more than 160cm;

otherwise, adopt structure B.

Provide the specification, tonnage, hoisting height of crane, hook space, and if it is double hook or not.

Provide the geometrical data (like length, width and thickness) and the pieces and layers that can be held once.