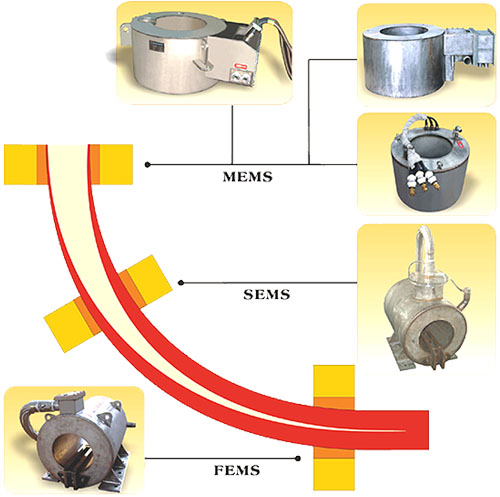

Classification of Electromagnetic Stirrer for billet/Bloom/Round

There are three kinds of EMS according to installation position:

1. Mould Electromagnetic Stirrer : M-EMS

2. Strand Electromagnetic Stirrer: S-EMS

3. Final Electromagnetic Stirrer: F-EMS

So far, most of steel plants use M-EMS or M+F-EMS.

Features of Electromagnetic Stirrer for Billet/Round

Mould EMS (M-EMS)

EMS inside mould using mould water: EMS is installed inside the mould and uses cooling water system of the mould. It can be operated conveniently with low cost. Stirring freq: 2 ~ 8Hz. (Refer to Fig.1)EMS inside mould using clean water: EMS is installed inside water jacket of the mould and uses a separate cooling water system. Structure is compact and life is long. Stirring freq: 2 ~ 8Hz. (Refer to Fig.2)EMS outside mould: EMS is installed outside the mould with separate cooling water system. It is simple to change copper tube. EMS can be used for wide range of sections. Stirring freq: 2 ~ 5Hz. (Refer to Fig.3)Inner cooling type ems:can be installed inside or out the mould.cramer windings are adopted,which has even magnetic field without polarization.But magnetic leakage is too much with electromagnetic pollution cooling water quality has to be very strict and operation cost is higher.Stirring freq is 1~ 6Hz. (Refer to Fig.4)

1. EMS inside mould using mould water

2. EMS inside mould using distilled water

3. EMS outside mould

4. EMS outside mould with copper pipe water cooling

Final EMS (F-EMS)

F-EMS uses rotate magnetic field with long iron core. Central magnetic induction is strong and application range is wide. Stirring effect shall be ensured with alternating or intermittent stirring.

Metallurgical effect of EMS for Bloom (Round)

| STIRRER LOCATION | METALLURGICAL EFFECTS | Steel Grades |

| Outside/inside the mould (M-EMS) | Increase equiaxed zoneReduce air holes, pinholes and inclusion in the surface and subsurfaceEqualize Billet CrustReduce central porosity a little

Reduce central segregation a little |

Low alloy steel Spring steel Cold rolling steel Medium and high carbon steel |

| in the strand (S-EMS) | Increase Equiaxed ZoneInprove Central SegregationReduce Inner CracksReduce central porosity and shringkage |

stainless steel tool steel |

| in the final (F-EMS) | Make equiaxed zone fineReduce central segregation Reduce central porosity and shringkage | spring steelbearing steelspecial high carbon steel |

Photos of Cross Section of Billet and round

Without EMS (carbon steel)

Without EMS (stainless steel)

With EMS (carbon steel)

With EMS (stainless steel)