General Description

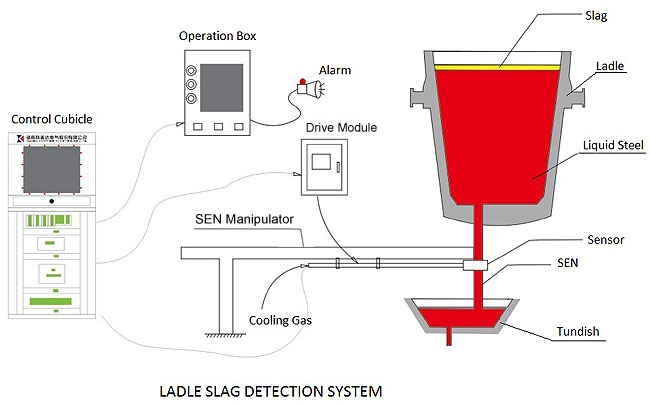

Ladle Slag Detection System(LSDS) is specially designed and manufactured by KEMEDIA(KMD) for monitoring slag intensity in liquid steel during liquid steel is being poured from ladle to tundish. The LSDS senor is mounted to the manipulator arm of ladle. When slag intensity reaches the set value, sound & light alarms will be given, and ladle gate can be closed in time. This design allows KMD LSDS to generate a reliable and accurate slag alarm far in advance of the slag detection of a human operator. So the user can maximize yield while greatly minimize slag carryover.

Control Mode: Manual, Semi-Auto or Auto.

Working Principle

LSDS sensor consists of two coils, one for transmitter (T) and the other receiver (R). T produces a steady magnetic field when powered by controlled AC current which is detected by R.

As tapping begins, SEN is totally filled with steel. The maximum signal shielding occurs and the receiver detects the minimum signal. Near the end of the tapping, slag begins to become entrained in the stream and appears in SEN. Since slag does not shield electromagnetic signals, the signal in the receiver begins to increase toward maximum. The received signal is directly proportional to the amount of slag in SEN. When the received signal reaches a certain predetermined set-point level, a slag alarm is activated.

System Configuration

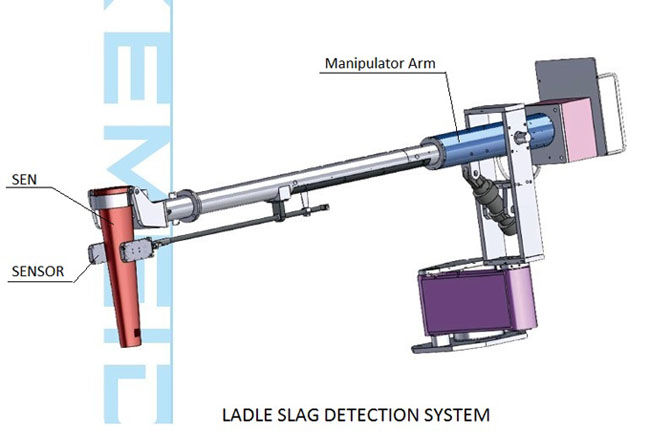

1. Sensor: U type. 2 nos ( one use + one spare)

2. Control Cubicle: 1 no

3. Local Operation Box: 1 no

Note:

1. Cooling gas: Argon or Nitrogen (Pressure 10-15kg/cm2)

Features:

1. Installation is easy and simple. No need to modify the ladle.

2. Maintenance is convenient. Only loose and fasten the nuts.

Being used in Ezhou Steel Ltd.